3D Printing Material Guide

3D Printing Material Guide lets you choose from when it comes to 3D Printing that it’s often tough to decide on the right one. But do not fear! ARCH GRAPHIC 3D Printing Materials Guide is here!

3D Printing Material Guide

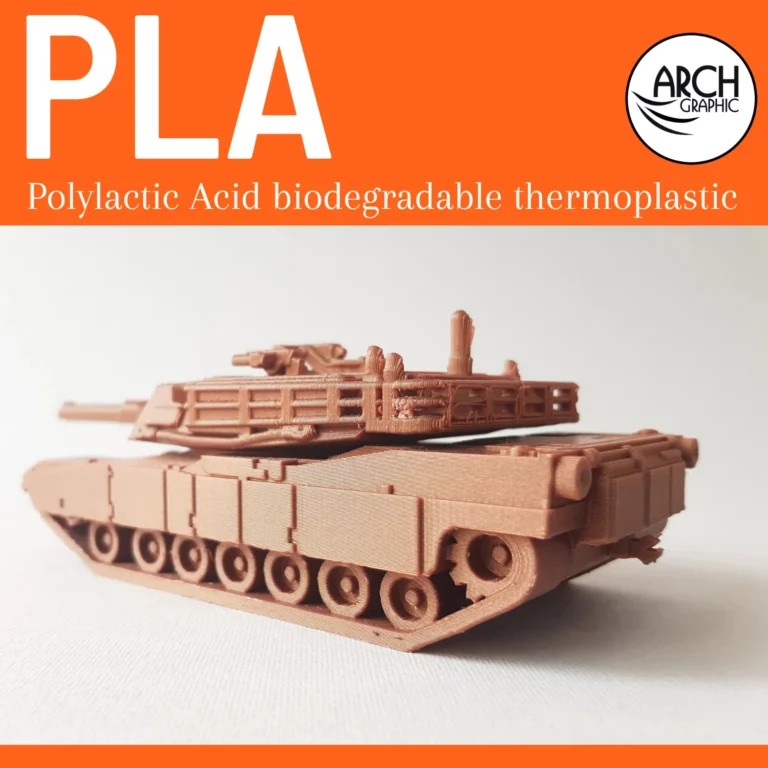

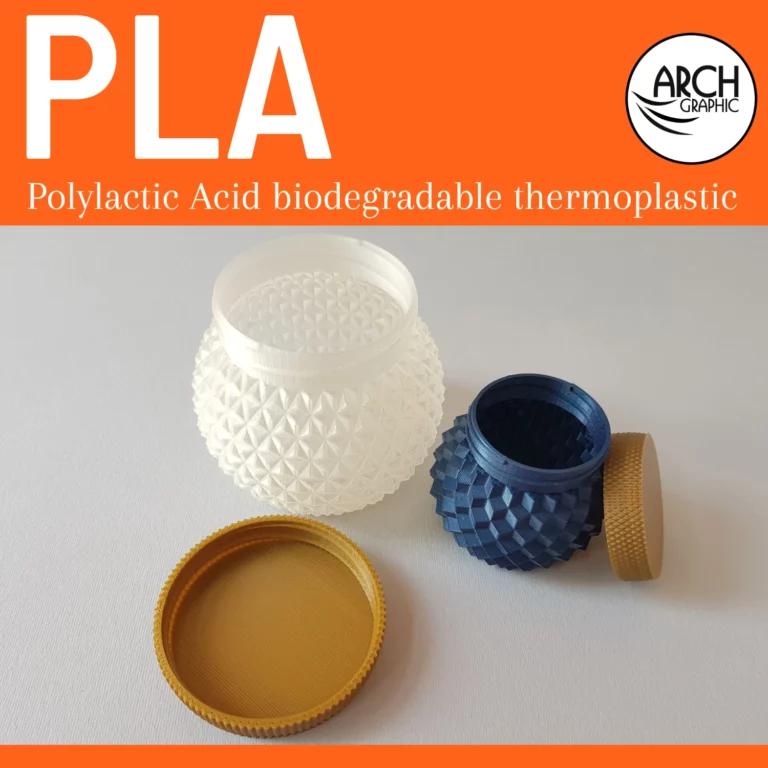

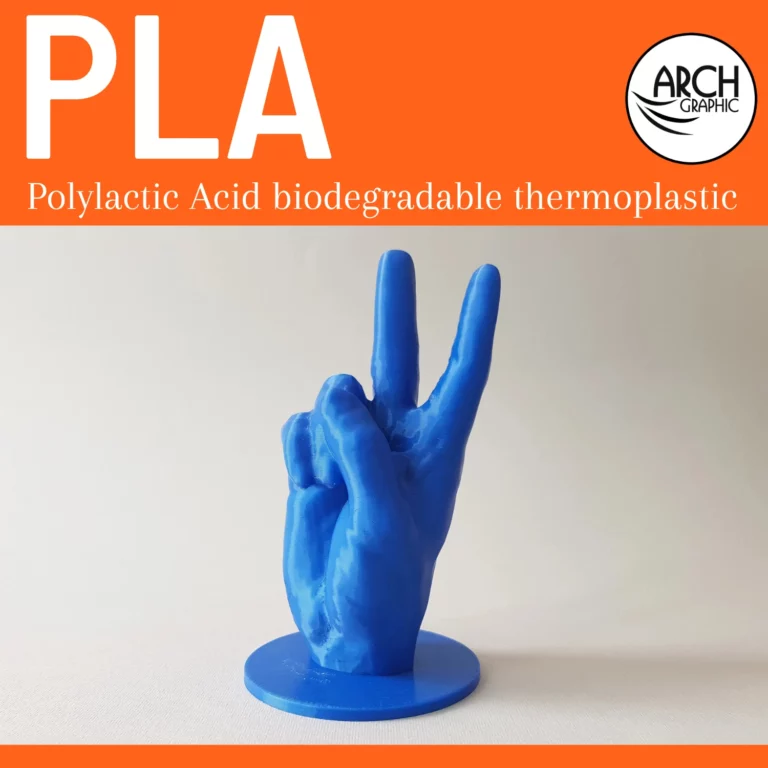

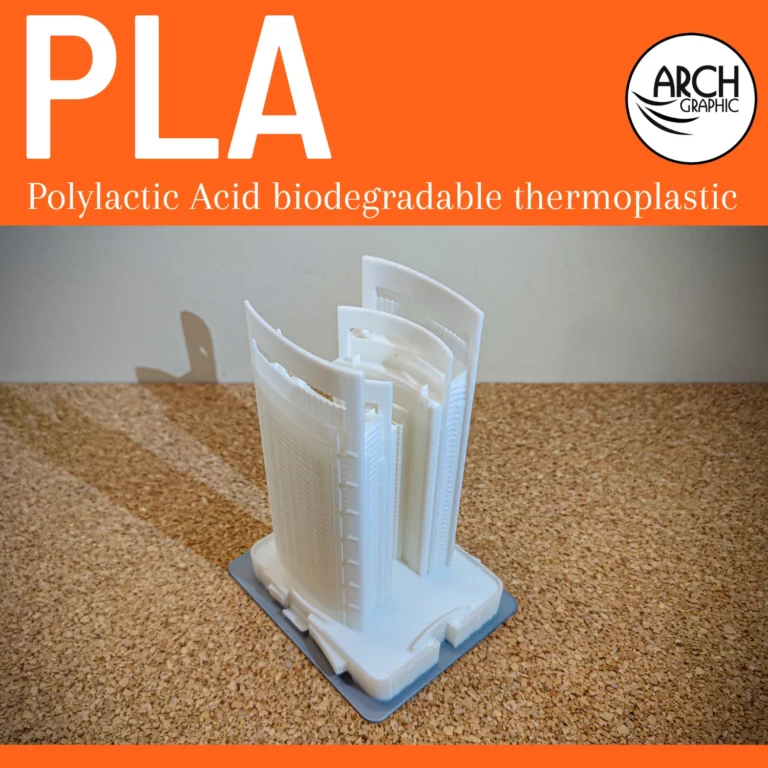

PLA

Polylactic Acid Biodegradable Thermoplastic

PLA is the go-to material for most users due to its ease of use, dimensional accuracy, and low cost.

Polylactic Acid is a biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. Is one of the most popular materials used for many applications ranging from plastic cups to medical implants. It is more cost-effective than ABS and is one of the budget options for 3D prototyping overall.

PROS

- Low Cost

- Stiff and good strength

- Good dimensional accuracy

- Good shelf life

- Biodegradable

- Wide variety of vivid opaque colors

CONS

- Low heat resistance

- Not suitable for outdoors (sunlight exposure)

3D Printing Material Guide

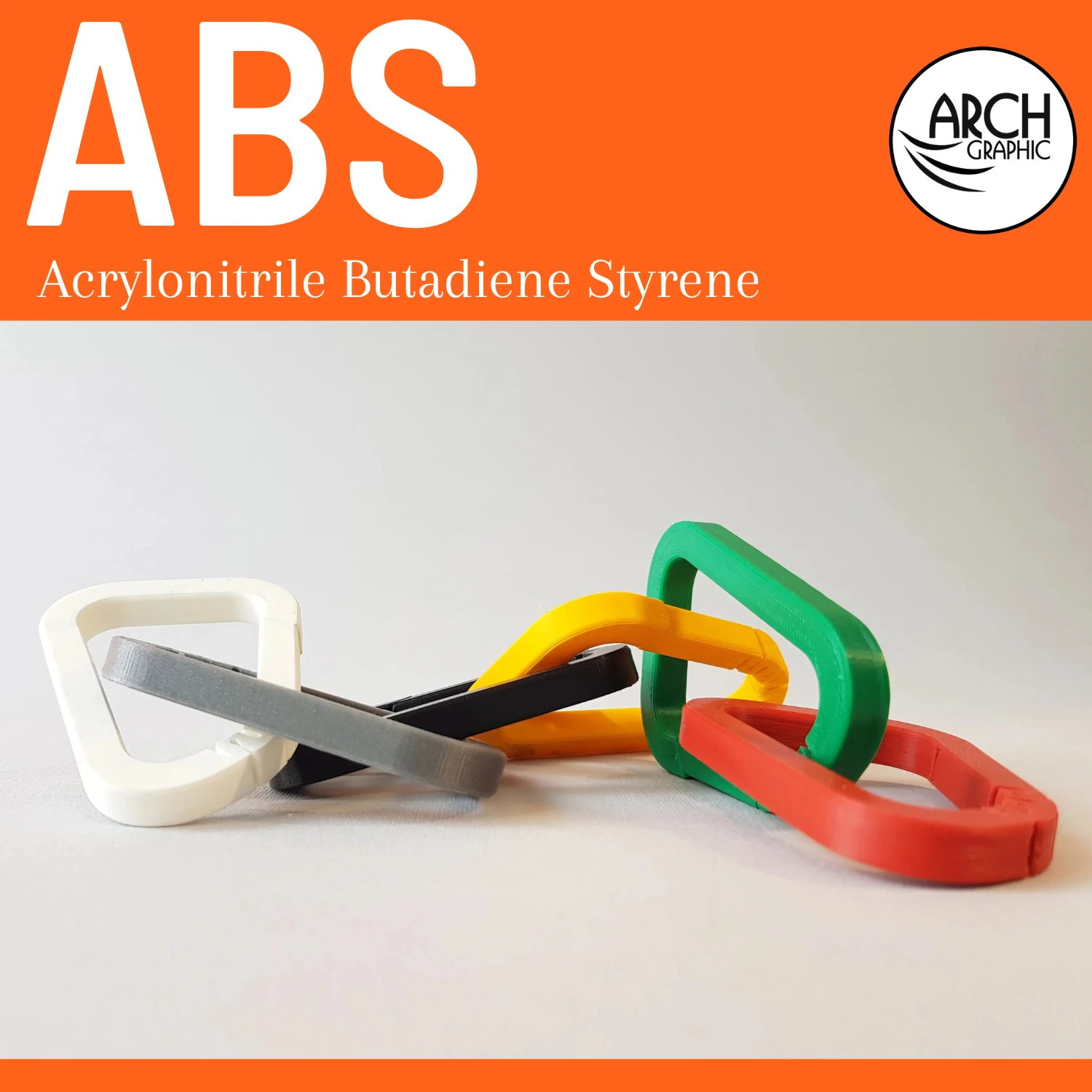

ABS

Acrylonitrile Butadiene Styrene

ABS is great for printing tough and durable parts that can withstand high temperatures.

Acrylonitrile Butadiene Styrene is a well-known thermoplastic, used for everyday applications such as LEGO, remote controls, electronic housings, and automotive parts. With good tensile strength, ABS is adequate for many prototyping applications, ABS also has a higher glass transition temperature, which means the material can withstand much higher temperatures before it begins to deform. This makes ABS a great choice for outdoor or high-temperature applications.

PROS

- High Cost

- Good impact and wear resistance

- Less oozing and stringing give models a smoother finish

- Good heat resistance

- Strong and durable

CONS

- Heavy warping

- Needs a heated bed or heated chamber

- Produces a pungent odor while printing

- Parts tend to shrink leading to dimensional inaccuracy

3D Printing Material Guide

PETg

Polyethylene Terephthalate Glycol

PET and PETG materials are known for their ease of printability, smooth surface finish, and water resistance.

PETG is a very tough substance with good thermal resistance and is especially suitable for mechanical parts and both indoor and outdoor use. PETG is of the same chemical composition as PET but with the addition of glycol. With just this one addition, the chemical composition is completely changed, creating a whole new plastic.

PROS

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

CONS

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

3D Printing Material Guide

ASA

Acrylonitrile Styrene Acrylate

ASA is a common alternative to ABS and is great for outdoor applications due to its high UV, temperature, and impact resistance.

ASA, also known as Acrylic Styrene Acrylonitrile, is a 3D printable plastic with properties similar to ABS. It was originally developed as an alternative to ABS that would be more UV resistant by changing the type of rubber that’s used in the formulation. ASA is known for high impact resistance, higher temperature resistance, and increased printing difficulty. It’s commonly used in outdoor applications instead of ABS due to its superior resistance to UV and harsh weather conditions. Due to its heritage.

PROS

- Strong UV resistance

- High impact and wear resistance

- The high glass transition temperature

CONS

- Expensive

- Requires higher extruder temperatures

- Requires ventilation due to potentially dangerous fumes

3D Printing Material Guide

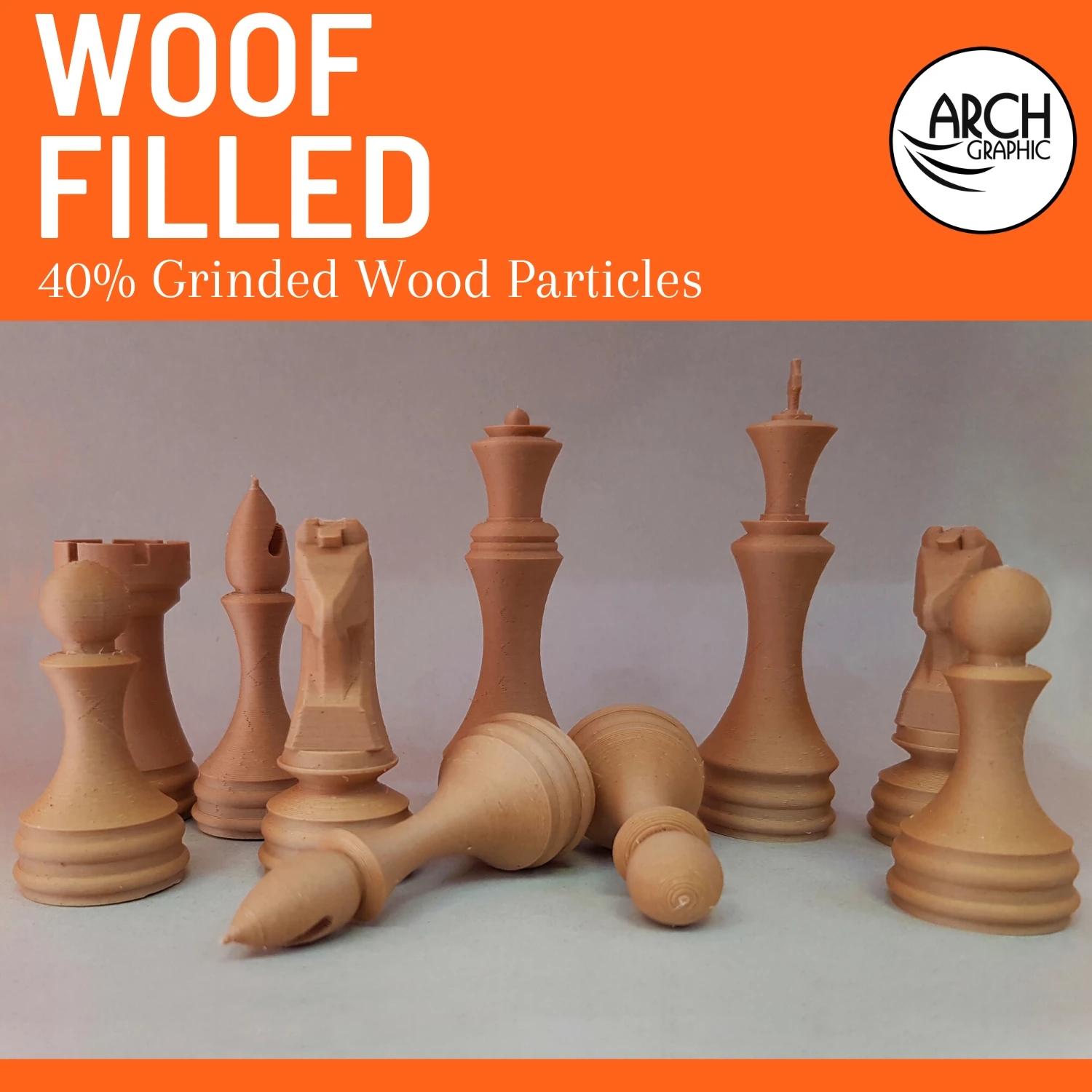

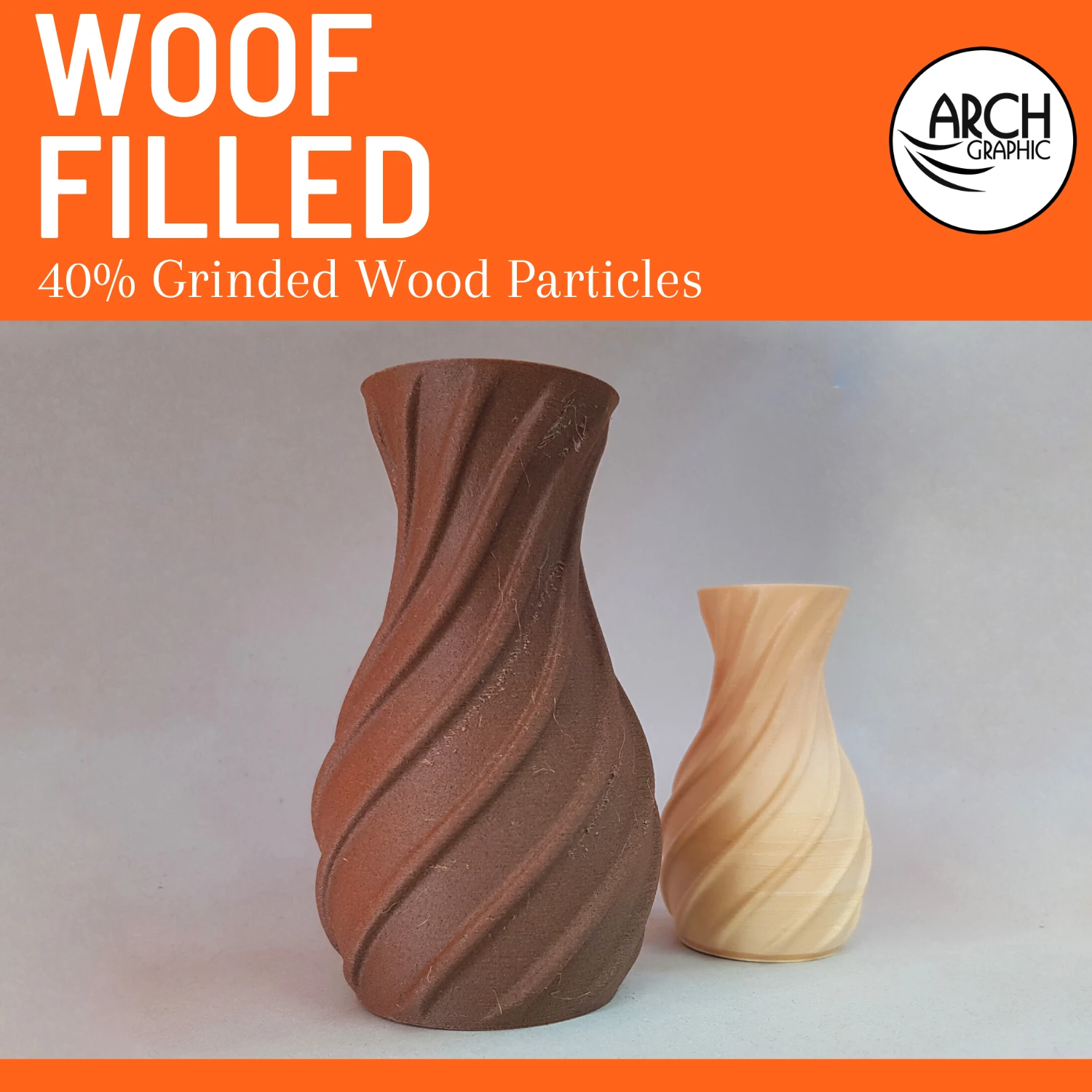

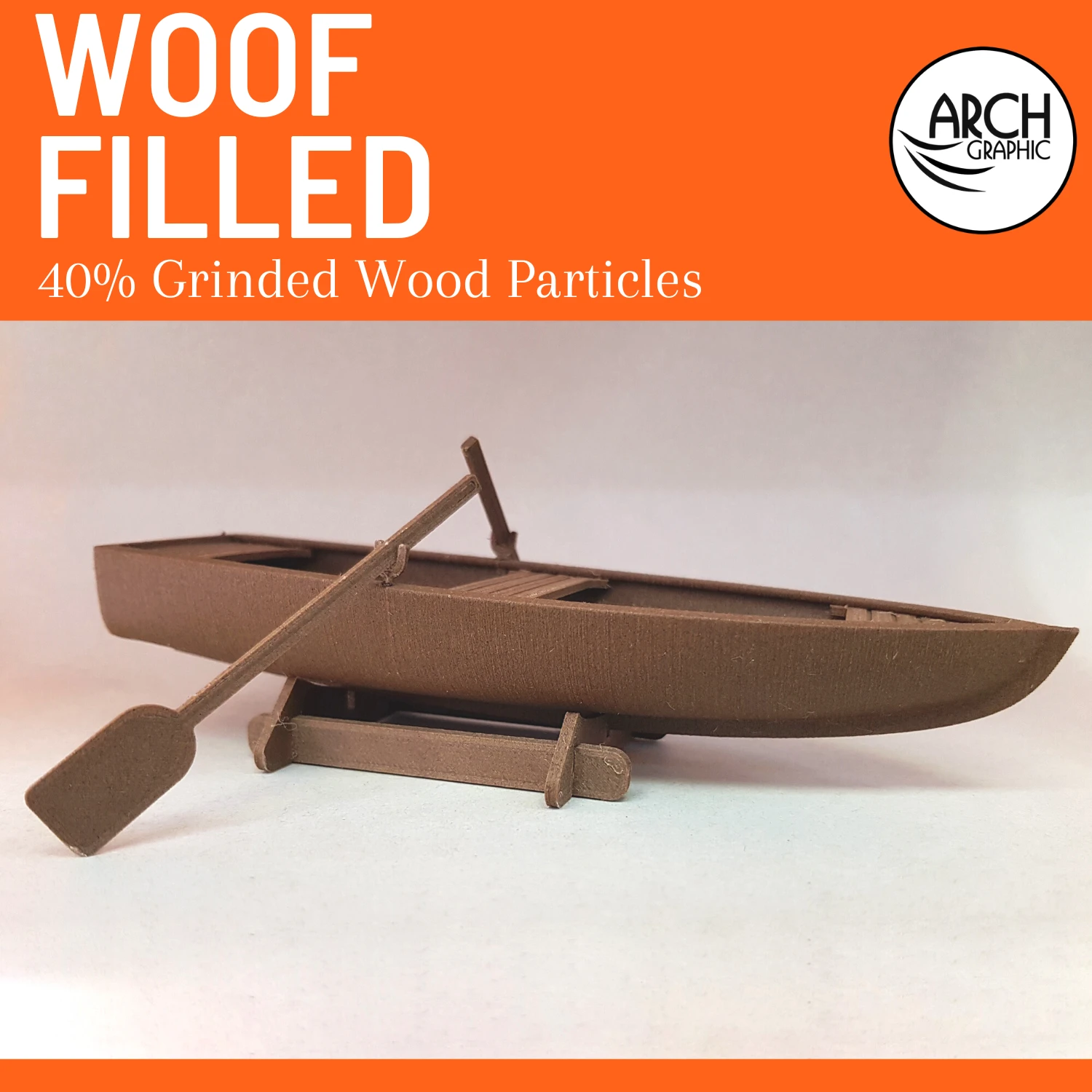

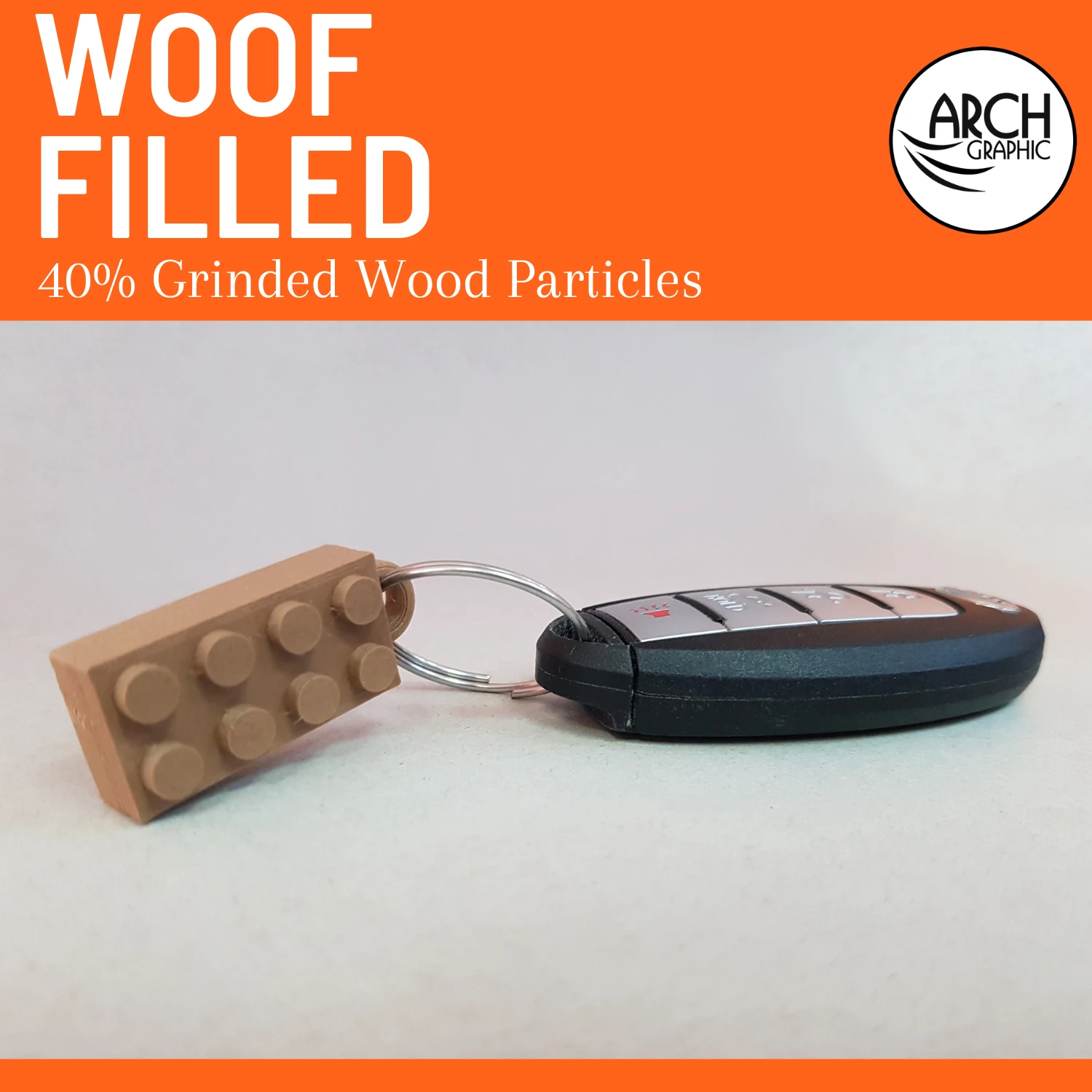

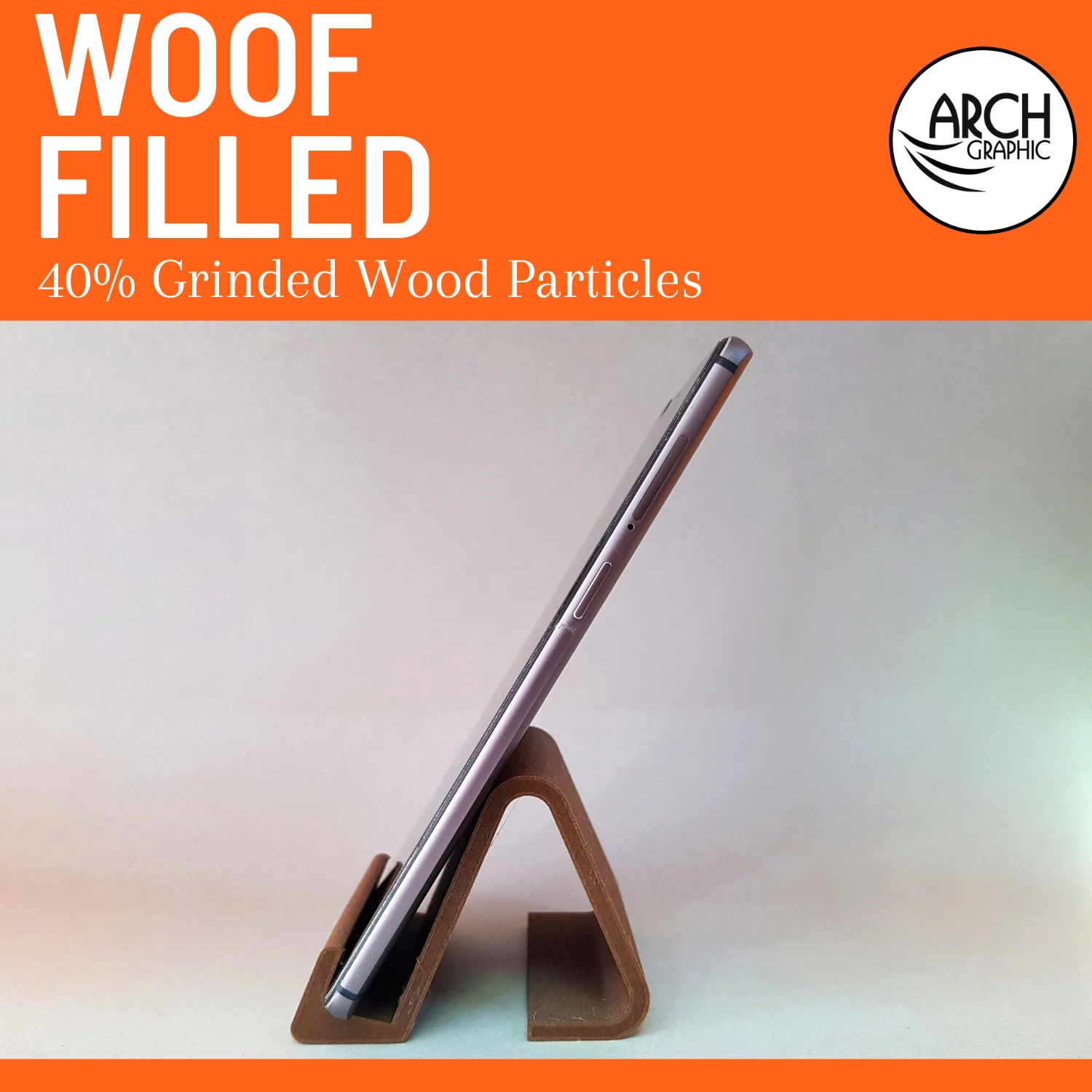

WOOD FILLED

40% Grinded Wood Particles

Wood material combines a PLA base material with cork, wood dust, or other derivatives, giving the models a real wooden look and feel.

Wood fill is a wood-filled PLA-based filament that is gravimetrically filled with approximately 40% grinded wood particles. Wood fill is 40% gravimetrical filling with grinded wood particles, wood fill looks feels, and smells like real wood and beautiful wood-nerve structures can be obtained by grinding the printed object a bit with a piece of fine grit sandpaper.

PROS

- The wood-textured finish is aesthetically appealing

- Does not need any expensive wear-resistant nozzles

- Aromatic and pleasant smelling

CONS

- Prone to stringing

- Smaller nozzles can end up with partial clogs over time

- It May require a larger size nozzle

3D Printing Material Guide

TPU

Thermoplastic Polyurethane

TPU material has a Perfect combination of strength, flexibility, and elasticity, with Heat resistance up to 138°C.

Flex is a high-performance flexible thermoplastic polyurethane (TPU) Material, TPU has a shore hardness of 98A and has great elastic properties as allows itself to be stretched up to 450% before breaking. TPU is extremely transparent in its natural form and has excellent resistance to oil, greases, microorganisms, and abrasion.

PROS

- Flexible and soft

- Excellent vibration dampening

- Long shelf life

- Good impact resistance

CONS

- Difficult to print

- Poor bridging characteristics

- Expensive

3D Printing Material Guide

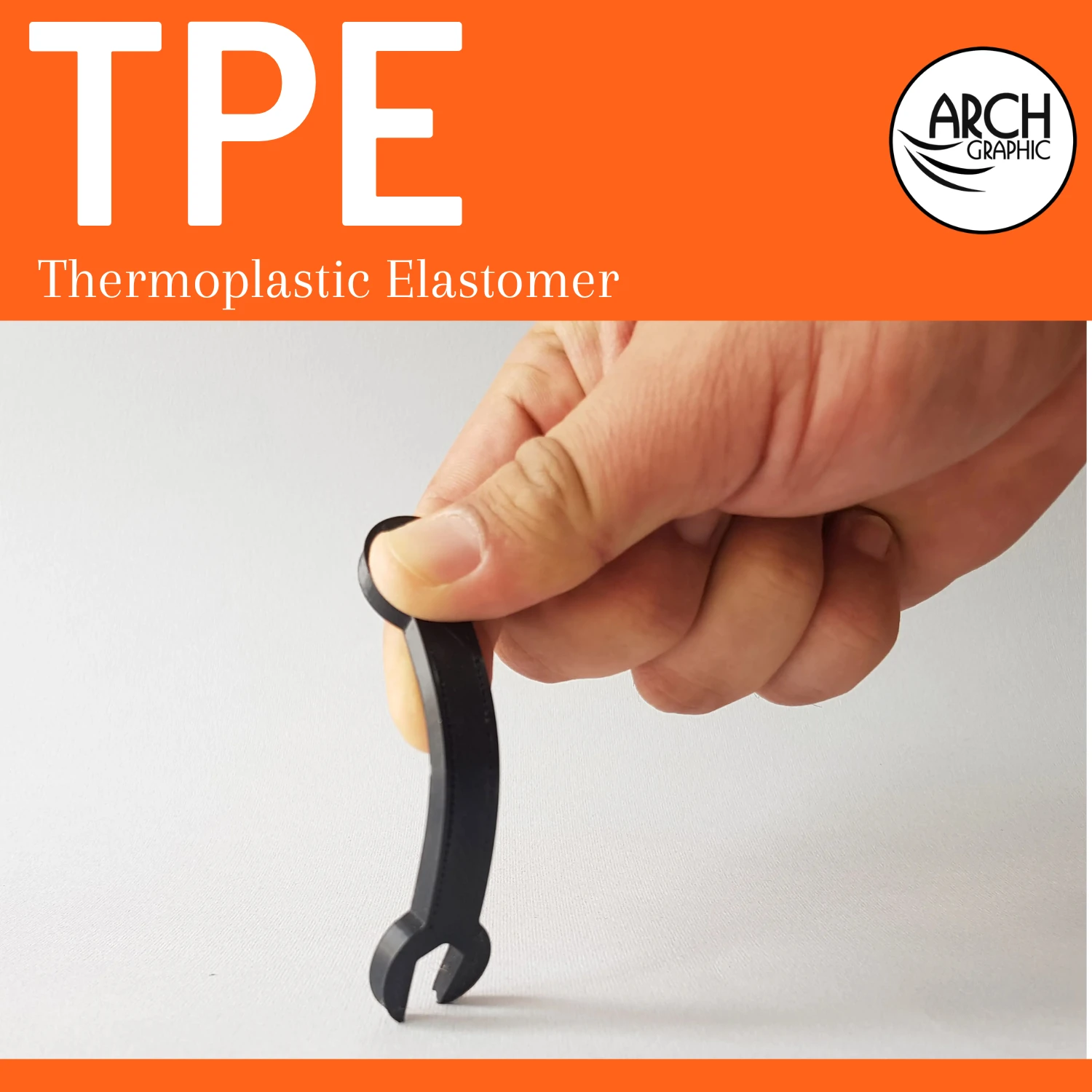

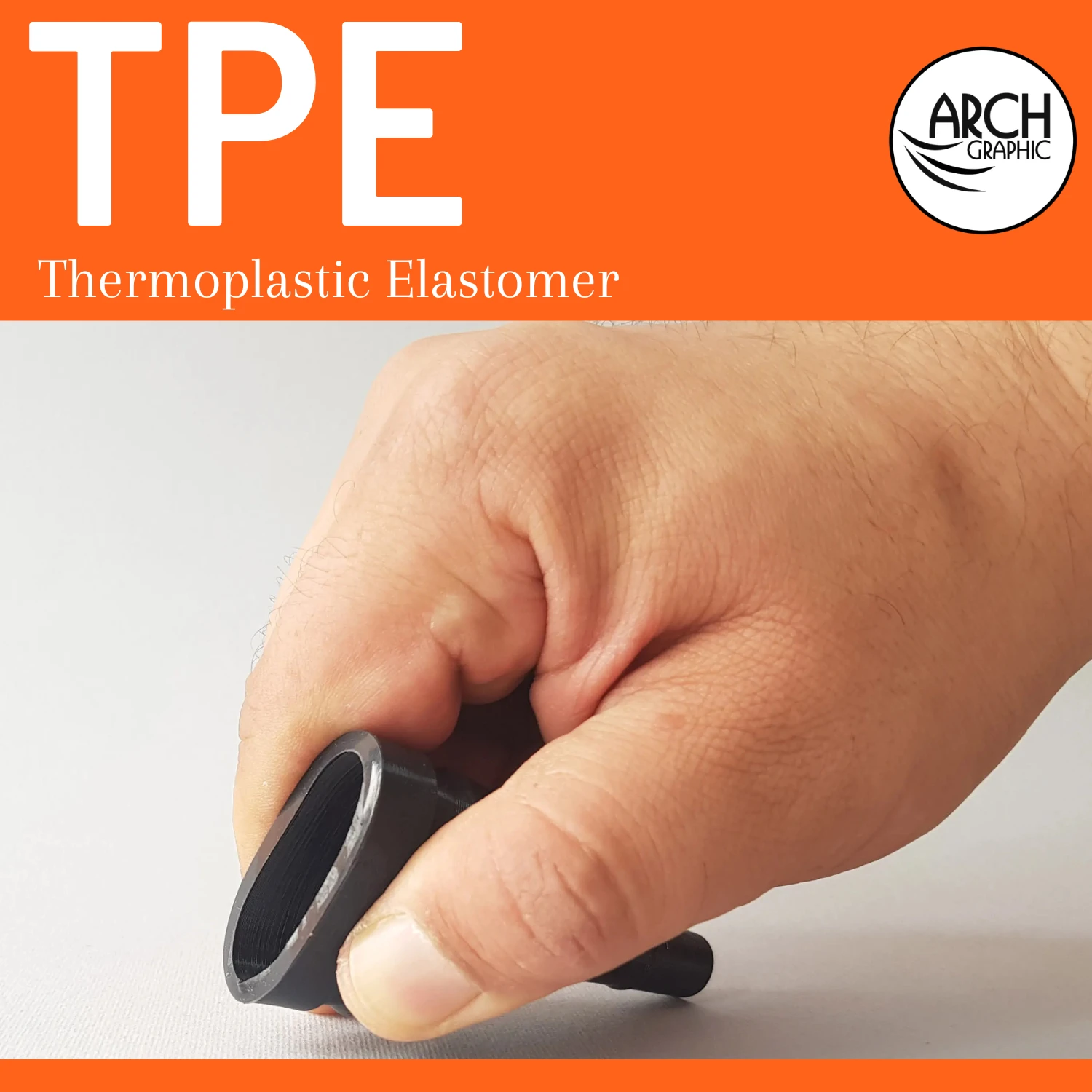

TPE

Thermoplastic Elastomer

TPE material has a Very flexible filament with “flexural memory”, a Shore hardness of 45D, High impact resistance, and Strong & durability.

TPE is a rubber-like high-performance and partially bio-based flexible TPC (Thermoplastic Co-Polyester) type of 3D printer material, TPE has unique flexural strength properties, as 3D printed objects with TPE will have a “flexural memory”, allowing objects to return back to their original position or shape after being bent, dent, or folded. Next to this, TPE offers a unique combination of flexibility, long-term heat resistance, strength, excellent UV resistance, and good resistance to chemicals.

PROS

- Flexible and soft

- Excellent vibration dampening

- Long shelf life

- Good impact resistance

CONS

- Difficult to print

- Poor bridging characteristics

- Expensive

3D Printing Material Guide

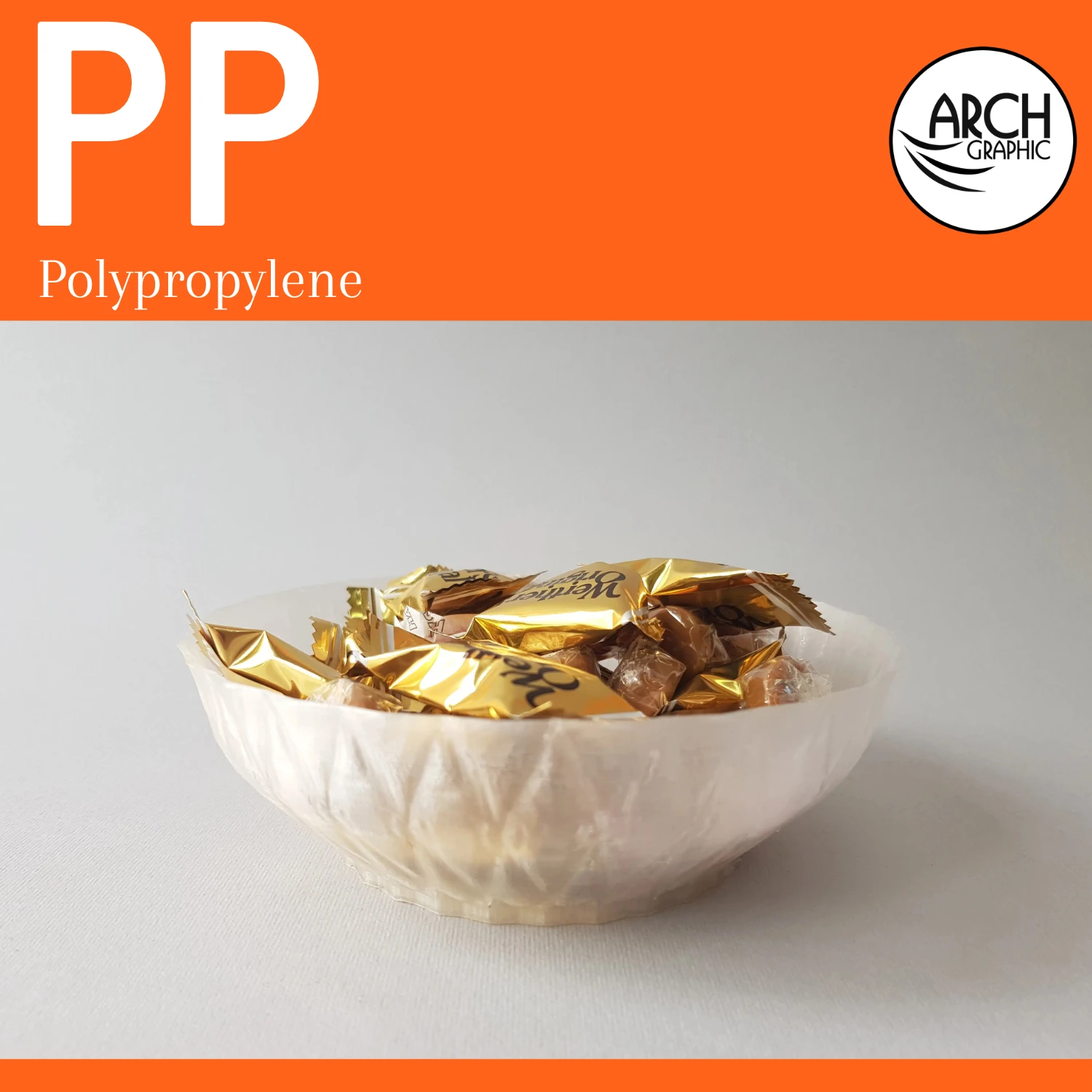

PP

Polypropylene

PP material is Food contact compliant, Dishwasher proof and microwave safe, and Lightweight with a Shore hardness of D50 and can be stretched up to >600% before breaking.

PP is a lightweight and high-performance Polypropylene (PP) Material, which makes Centaur PP an extremely diverse and multi-functional material suitable for numerous applications ranging from 3D printing dishwasher-proof and microwave-safe household articles to functional engineering objects with great endurance properties.

PROS

- Food contact compliant

- Dishwasher-proof and microwave safe

- Lightweight

- High chemical resistance

- Shore hardness of D50

- Can be stretched up to >600% before breaking

CONS

- Difficult to adhere to bed and other adhesives

- Expensive

3D Printing Material Guide

NYLON

Polyamide Microcrystalline

Nylon is a tough material that offers high impact and abrasion resistance. It is an ideal choice for printing durable parts.

Alongside both PLA and ABS, Nylon, also known as polyamide, It has extreme strength and durability. The material is also the choice of many that require finishing like screwing, tapping, or drilling, Nylon-12 is an industrial PA12 grade nylon Material that combines excellent mechanical.

PROS

- Tough and partially flexible

- High impact resistance

- No unpleasant odor while printing

- Good abrasion resistance

CONS

- Prone to Warping

- Air-tight storage is required to prevent water absorption

- Improperly dried filaments can cause printing defects

- Not suitable for moist and humid environments

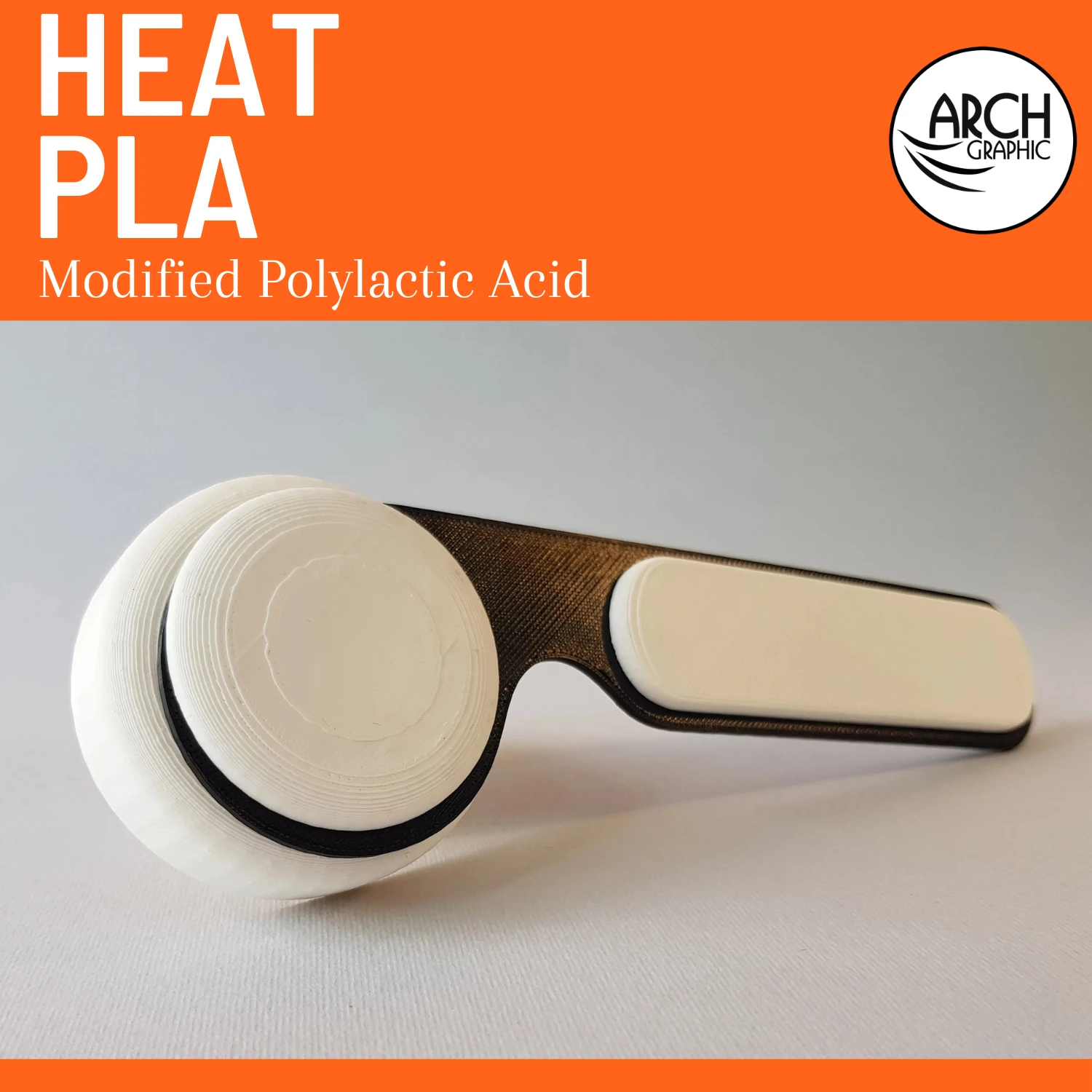

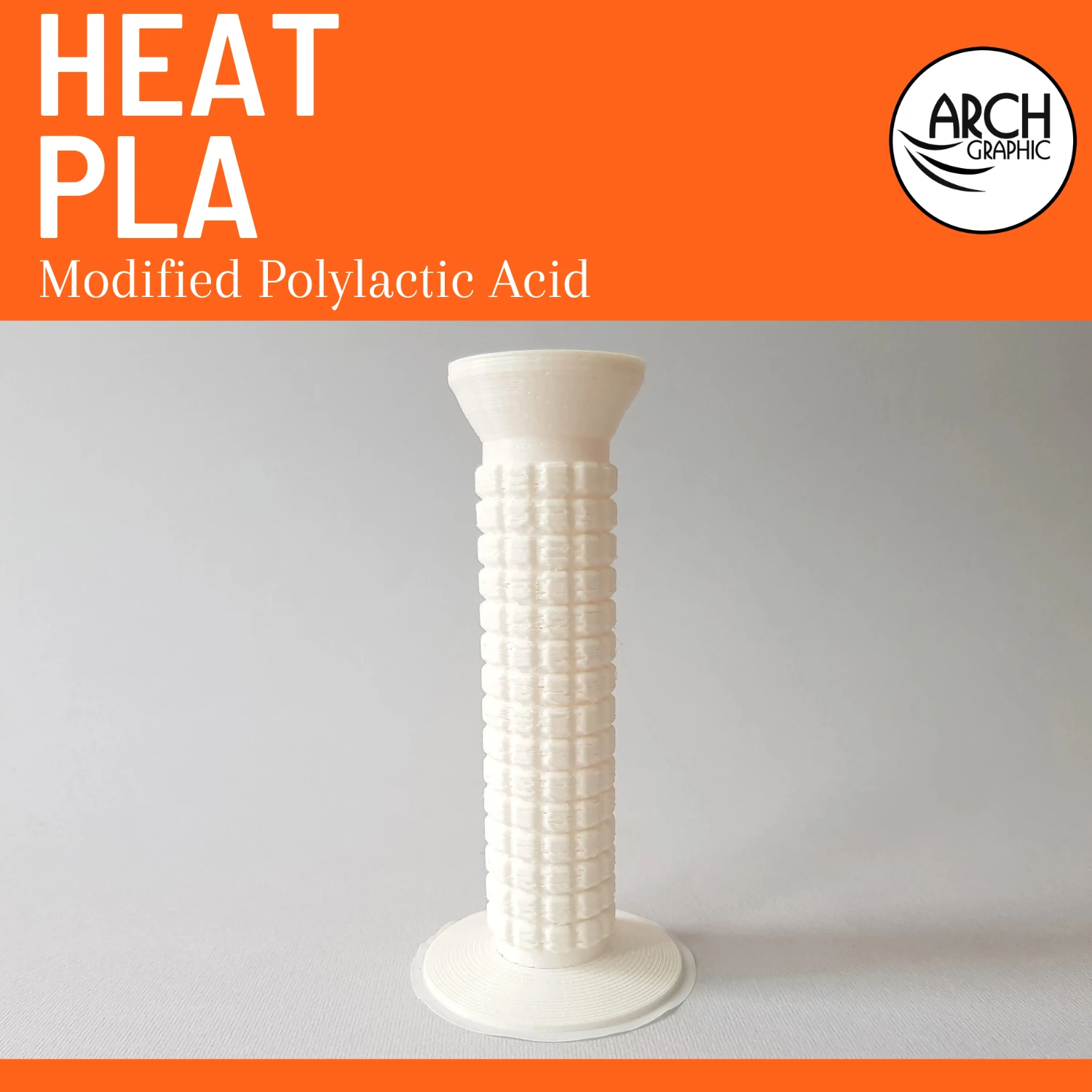

3D Printing Material Guide

Heat PLA

Modified Polylactic Acid

Heat PLA is High heat resistance of ≥ 95° C after annealing, with Roughly 8 times less shrinkage compared to competitor materials available on the market.

Heat PLA is an industrial-grade PLA that is engineered for professional applications that require high printing speeds and improved heat resistance and mechanical properties similar to ABS. Heat PLA offers the same mechanical and thermal properties – after annealing – as most ABS Materials, but with the biodegradability of PLA, Heat PLA combines high heat resistance with high printing speeds and high impact resistance into a PLA-based filament engineered for industrial applications.

PROS

- Biodegradable

- Matte surface finish

- High heat resistance of ≥ 95° C after annealing

CONS

- Not accurate dimensions

- Low quality compared with normal PLA

3D Printing Material Guide

CARBON FILLED

Modified Polyethylene Terephthalate Glycol

Carbon Filled is Great impact resistance, extremely stiff, and Reinforced with 20% ultra-lightweight and relatively long carbon fiber stringers.

Our Carbon Fill Material is based upon the unique PETg blend reinforced with 20% ultra-light and relatively long stringer carbon fibers, which has resulted in an exceptionally stiff carbon-fiber reinforced 3D printer material. Carbon Fill is twice as stiff as PETg and yet it is even 10% more impact resistant, which is a remarkable feature for carbon-fiber reinforced Material.

PROS

- Increased strength and stiffness

- Very good dimensional stability

- Lightweight

CONS

- Abrasive and requires a hardened steel nozzle

- Increased oozing while printing

- Increased brittleness of filament

- Higher tendency to clog